Regeneration Prosthesis

INDUSTRY 4.0

PROJECT THEME / Furture Low-cost prosthesis

DURATION / 2021.10-2021.12, 3 months

PROJECT TYPE / Group

The process of fitting a prosthetic hand that is a comfortable, functional, easy to use, has an acceptable appearance and overall improves the amputees’ quality of life is a complex, tedious and costly process. The very high price tag due to the time spent on manually fitting the device by a trained specialist makes these devices inaccessible to large portions of the population. At the same time, 3D printing technology is being continuously promoted. In the future of industry 4.0, 3D printing will be inseparable from industrial production, which will also accelerate the production efficiency of personalized prosthetics and make the customization process and production process more flexible.

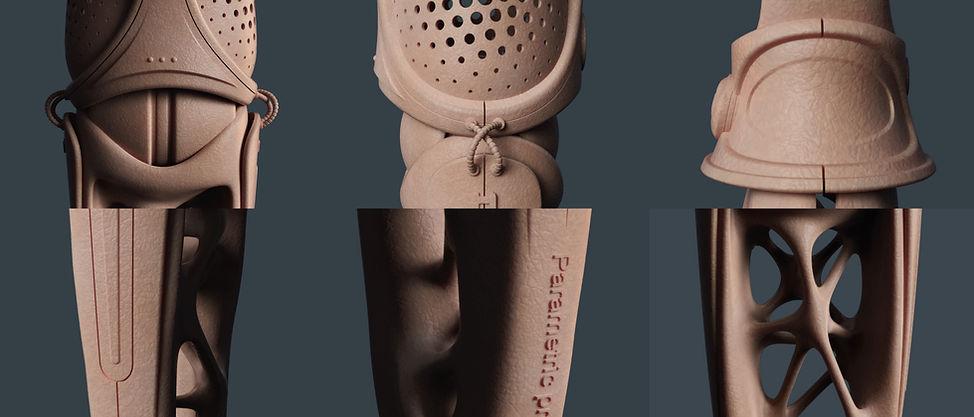

I present a concept and preliminary results for a fully automated fitting and manufacturing pipeline for a fully automated low-cost prosthesis. “Regeneration” prosthesis is personalized in almost every aspect, from appearance to user interface, control and feedback.

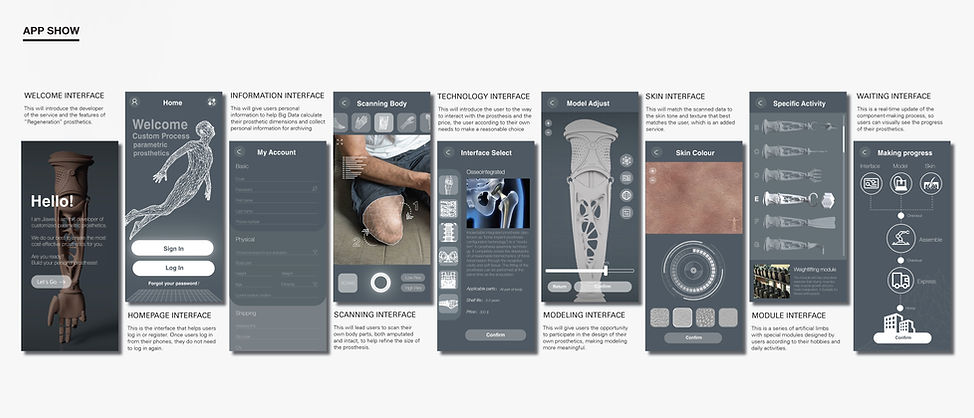

The "Regeneration" prosthetic is a low-cost version of the APP that allows amputees to experience the whole process of making a new prosthesis. The APP offers services such as scanning the phone's camera, selecting an interface, modifying the shape and selecting the skin. Through this series of "regeneration" process, amputees are given a new user experience.

In terms of core technology, the Ameba calculation plug-in is applied to the customized modeling to generate the minimum material model with the required strength. The Ameba calculation plug-in is applied to the prosthetic modeling so that amputees can choose the solution with the least materials to pay a reasonable price in the customized service process.

The production process only requires a 3D printer, a few basic mechanical components and basic tools for the model assembly. At the same time, our production center will save the files of amputees for their next customization, and the STL files will always be saved on the cloud platform if it is allowed by the amputees. We believe that the proposed design can substantially improve quality of life for amputees and could potentially be expanded to other medical applications.